Can Epoxy Floor Coating Be Used Outdoors? Limitations & Professional Alternatives | SPR Paint Floor Coatings

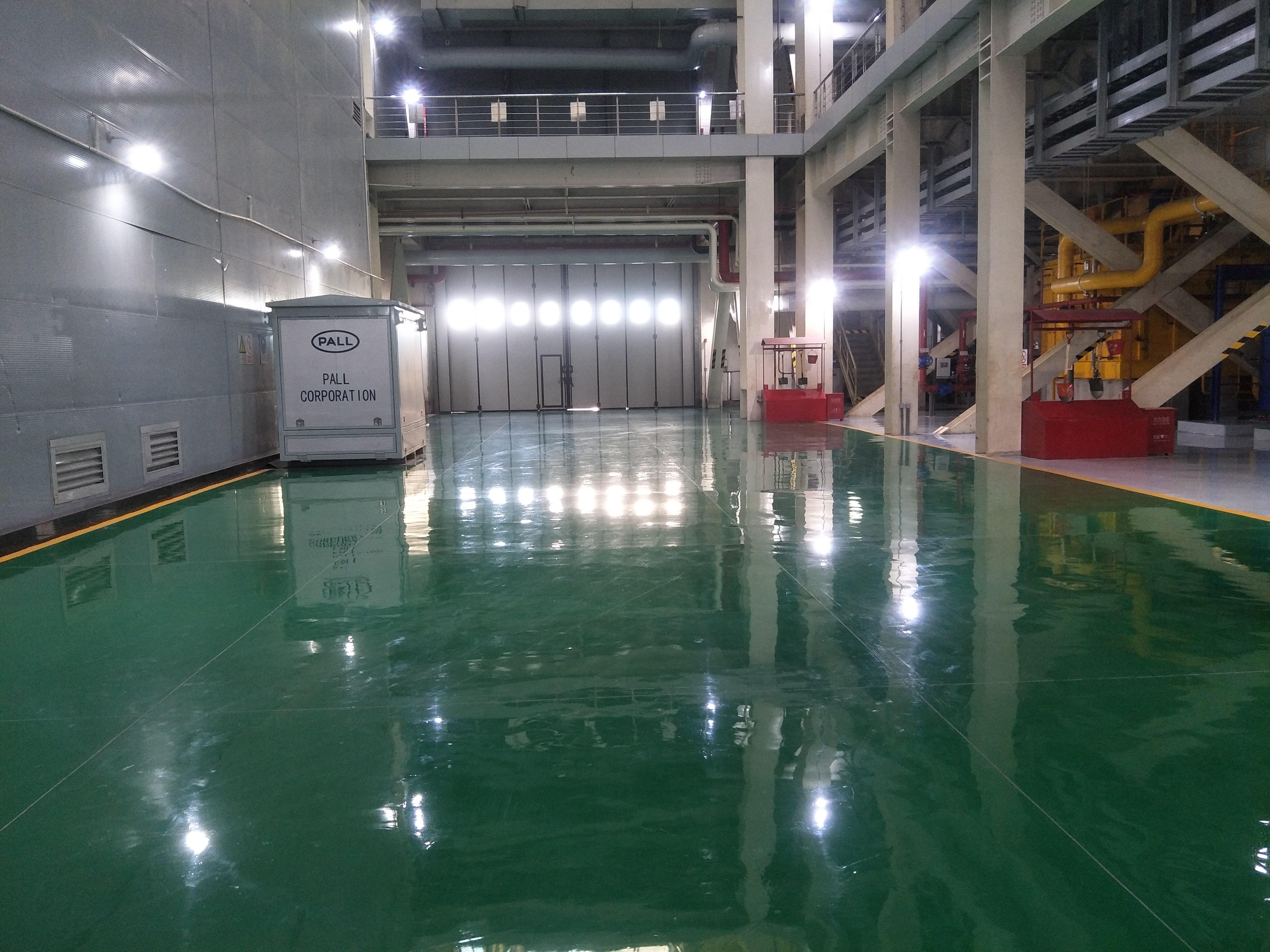

Epoxy floor coatings dominate indoor industrial spaces with superior abrasion resistance, seamless surfaces, and chemical stability. However, for outdoor applications, their limitations are critical. As specialists at SPR Paint, we explain why epoxy often fails outdoors and recommend superior alternatives.

I. Core Weaknesses of Epoxy in Outdoor Environments

While unmatched indoors, epoxy’s vulnerabilities outdoors include:

UV Degradation : Sunlight decomposes epoxy resins, causing chalking, fading, and gloss loss.

Thermal Stress Cracking : Temperature swings (>30°C ΔT) trigger delamination.

Moisture Damage : Humidity >75% + freeze-thaw cycles cause blistering.

Accelerated Chemical Attack: De-icing salts/acid rain corrode epoxy 3× faster than indoor chemicals.

II. Strictly Limited Outdoor Use Cases

Epoxy coatings may only be considered in:

Fully sheltered zones (e.g., covered walkways, enclosed parking entries).

Short-term projects (<2 years lifespan).

Hybrid systems with SPR Paint’s UV-resistant primers and aliphatic polyurethane topcoats.

Warning: Even optimized systems last 50% shorter than true outdoor coatings.

III. Recommended Outdoor Flooring Solutions

For durable outdoor performance, choose these specialized systems:

Polyurethane Coatings: Best overall for UV stability, flexibility (500% elongation), and chemical resistance. Ideal for parking lots and exposed platforms. SPR Paint Solution: PolyShield EX series.

Acrylic Coatings : Cost-effective, color-stable option for sports courts/pedestrian paths. SPR Paint Solution: AcryLite SportsFinish.

Concrete Sealers + Dyes : Penetrating sealers harden concrete (200% hardness gain) with zero delamination risk. Perfect for heavy-traffic yards. SPR Paint Solution: DensifierPro HD.

Pervious Concrete: Eco-friendly drainage solution for parks/stormwater zones.

IV. Key Decision Guidelines

Avoid epoxy in exposed outdoor areas.

Prioritize weathering resistance (ASTM D4796 compliance).

For heavy traffic: Choose polyurethane coatings or sealed concrete.

For tight budgets: Acrylic coatings deliver 10+ year durability.

For ecological needs: Pervious concrete prevents flooding.

SPR Paint Professional Insight: "Repairing failed epoxy costs 3× initial savings. Invest correctly with our Outdoor Durability Audit."