What Flooring to Choose for Warehouses? 3 Top Solutions

What Flooring to Choose for Warehouses? 3 Top Solutions Compared - Epoxy Floor Coating Dominates!

As operational hubs, warehouse floors directly impact logistics efficiency, cargo safety, and maintenance costs. Selecting durable, low-maintenance floor coatings or systems is critical. Among all solutions, these three dominate the market for their proven performance:

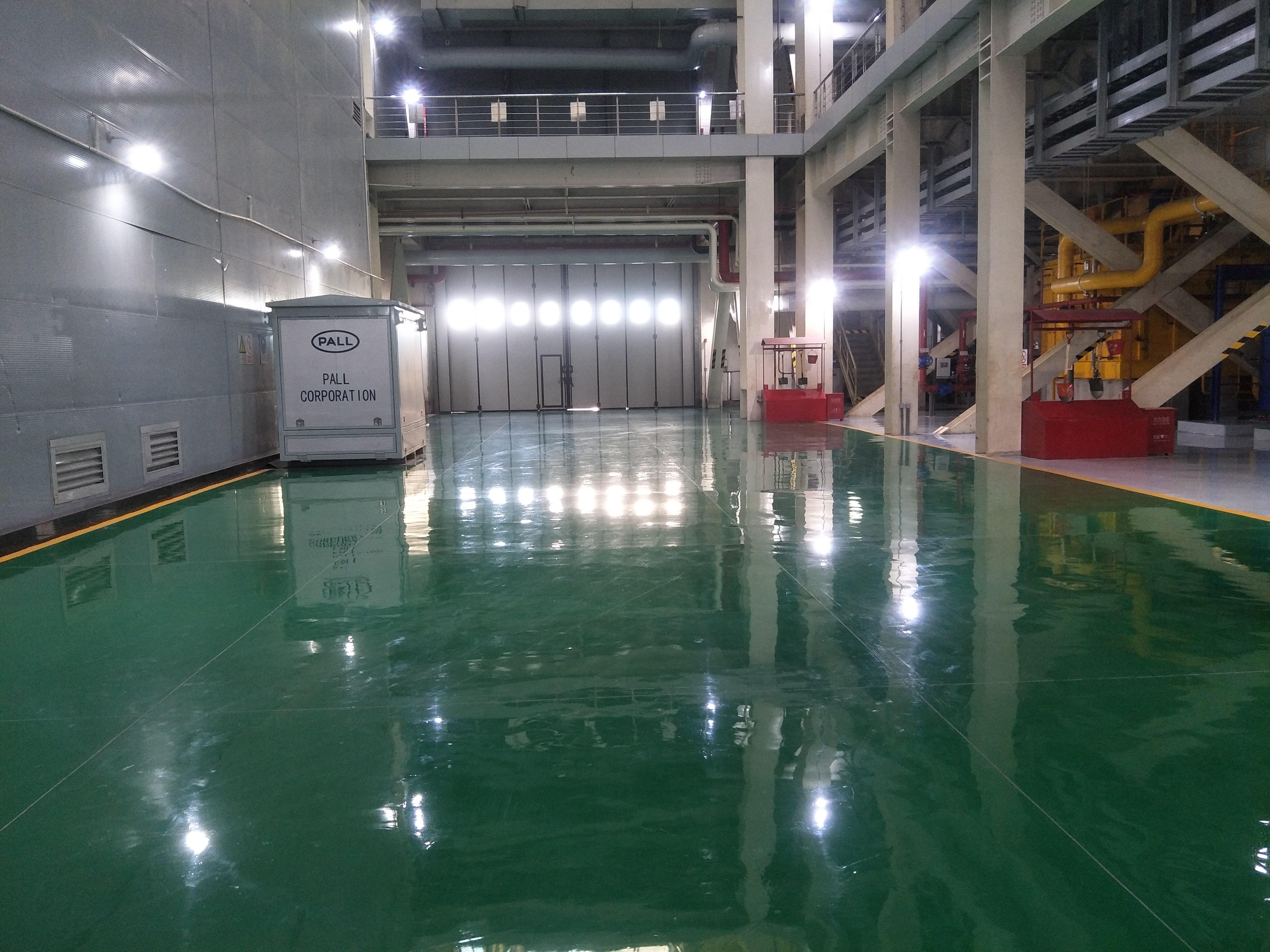

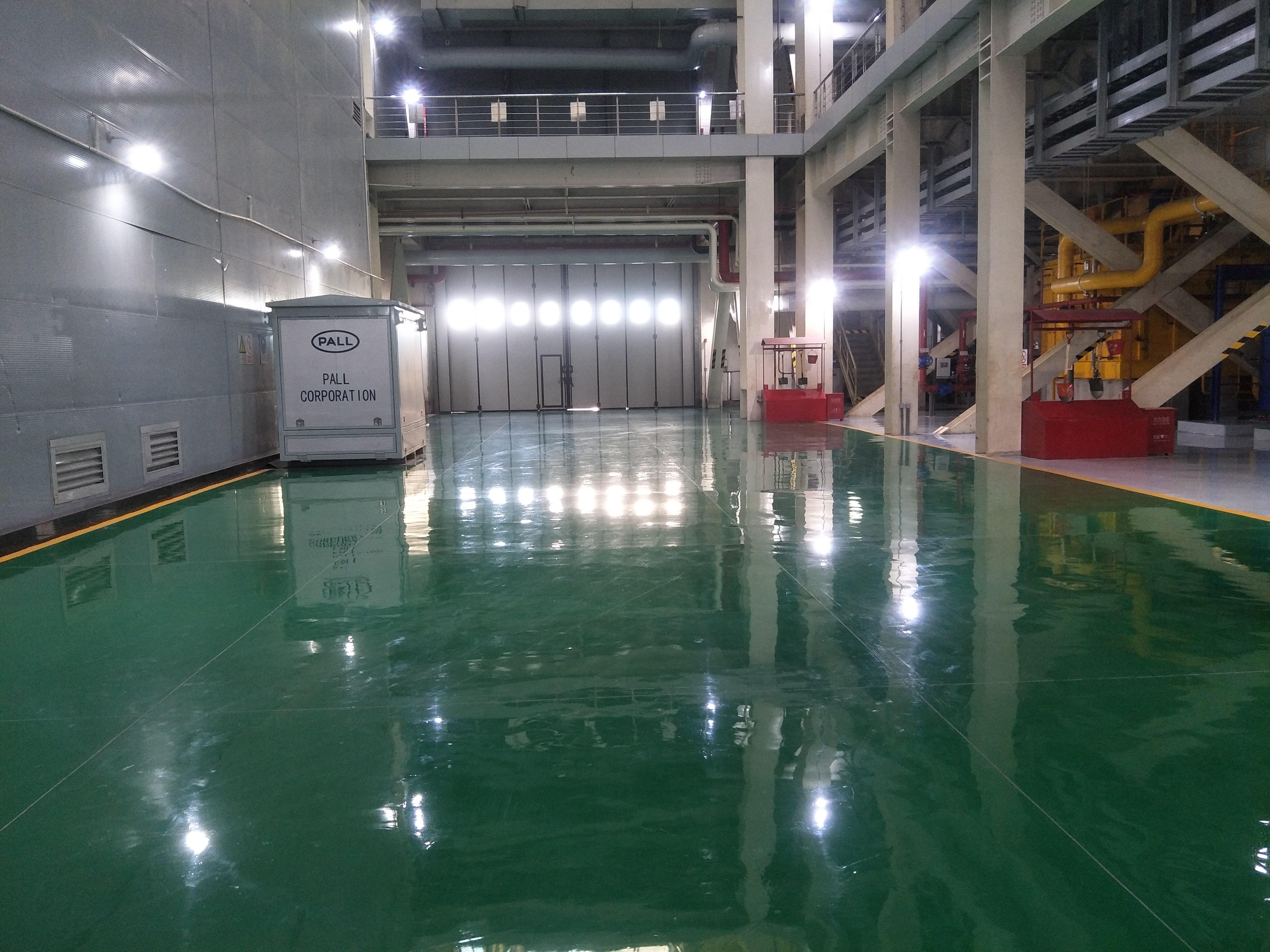

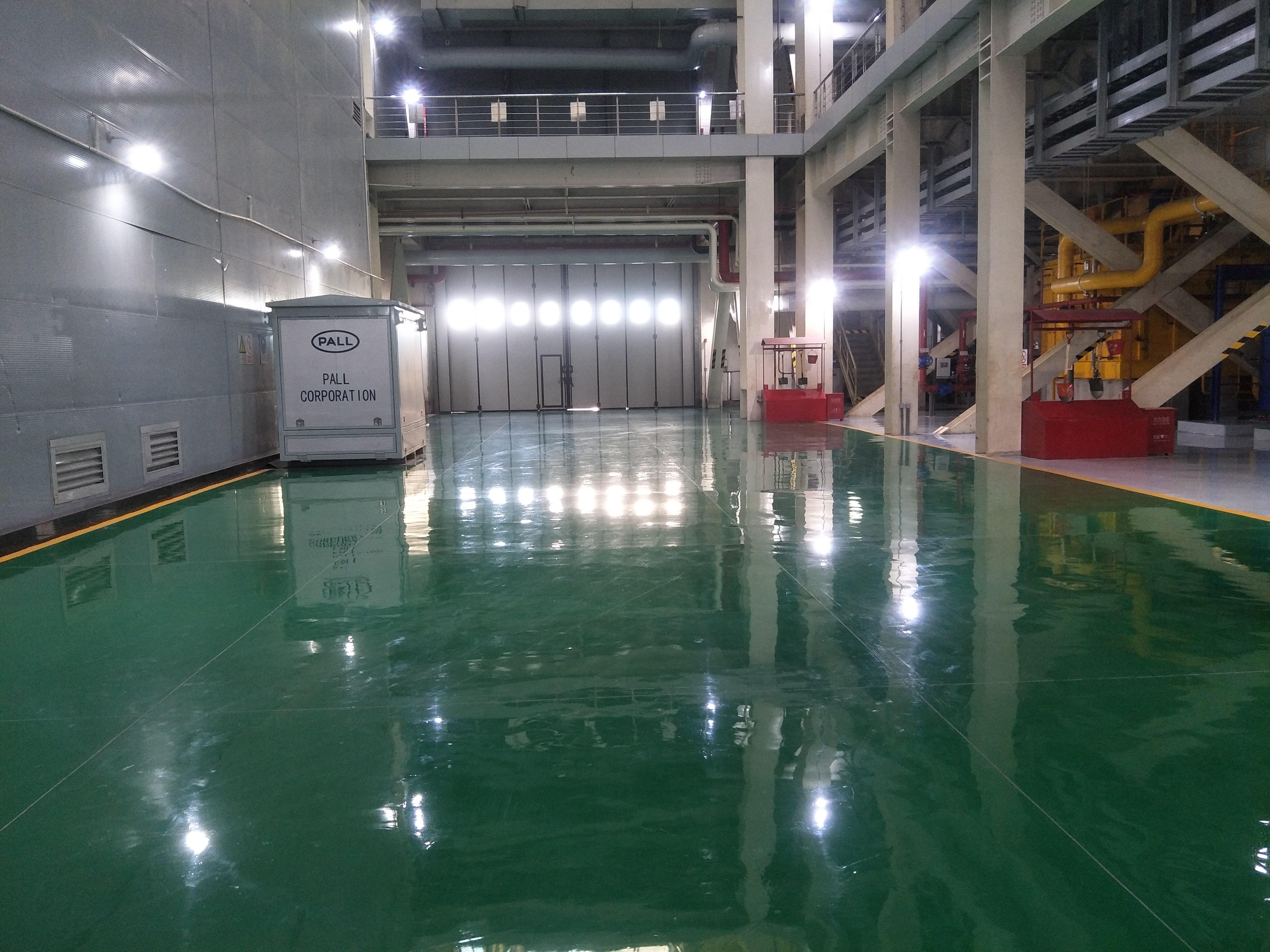

1. Epoxy Floor Coating: Ultimate Protective Shield

Core Advantages:

Extreme Hardness (ASTM D3363: 4H+) & Superior Wear Resistance (Taber test ≤30mg/1000 cycles)

Impact resistance up to 15kJ/m² (ISO 6272) - withstands forklifts, racking, heavy loads

Key Features:

Seamless, Dust-Proof Surface - Critical for food/pharma/electronics warehouses

Easy Cleaning - Spills wipe off; reduces sanitation costs by 40-60%

Chemical Resistance (Optional) - Blocks oil, acid, solvent penetration

Custom Aesthetics - Gloss/matte finishes; color-coding zones

Best For: E-commerce FCs, cold storage (-30°C rated formulations), high-value product warehouses

2. Polished Concrete + Topping: Economical "Iron Warrior"

Core Process: Diamond-cut concrete surface + metallic aggregate broadcast during pouring + sealer/hybrid coating

Core Advantages:

Ultra-High Abrasion Resistance (ICRI-CSP 9+)

Lower Initial Cost - Integrated with slab construction

Critical Enhancement:

Requires penetrating sealer or thin epoxy/polyurethane coating to prevent dusting and enable cleaning

Best For: Budget warehouses, heavy-traffic cross-docks, logistics hubs

3. Modern Terrazzo Flooring: Durable & Designer

Evolution: Epoxy/resin-based binders replace cement → Epoxy Terrazzo Coating

Core Advantages:

Slip-Resistance (DIN 51130: R10-R12) from exposed aggregates

Seamless & Repairable - Grind/polish damaged sections

Custom Designs - Colored chips, logos, directional patterns

Best For: Showroom warehouses, creative campuses, mixed-use spaces