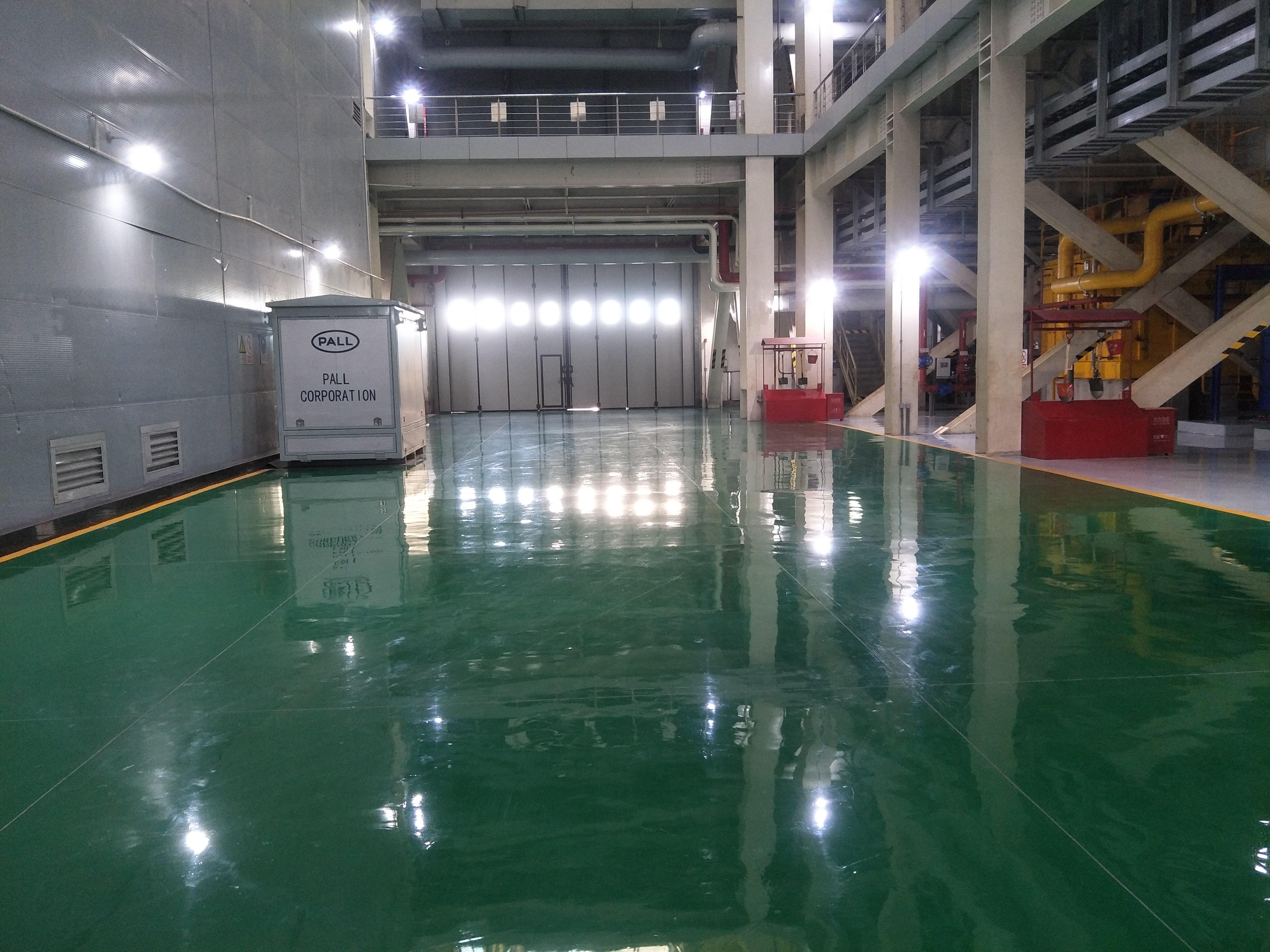

How to Select Epoxy Anti-Static Flooring Materials?

Selecting epoxy anti-static flooring materials requires specialized knowledge and meticulous consideration, as it directly impacts performance,

durability, and safety. The selection process should follow scientific principles aligned with practical needs to ensure optimal static control while

meeting environmental demands.

Key Selection Criteria:

Usage Environment Analysis:

Electronics/Precision Manufacturing: Prioritize materials with ultra-high static dissipation (surface resistance 10⁴–10⁶ Ω).

Chemical Exposure Zones: Require chemical-resistant formulations (acid/alkali/solvent tolerance).

Durability Performance:

Essential properties: Abrasion resistance (ASTM D4060 Taber test ≤50mg/1000 cycles), impact resistance (ISO 6272 >15kJ/m²).

Target 10+ year service life to minimize maintenance costs.

Aesthetic Requirements:

Seek seamless, high-gloss finishes (≥80° gloss units) with color consistency.

Environmental Compliance:

Mandatory low-VOC certification (LEED-compliant, VOC <100g/L).